Centuary FIBC Infrastructure is a culmination of seamless process comprising of plants and machines all working in harmony to deliver great bulk packaging solution on time. Our facility is equipped with latest equipment and technologies to ensure fast, reliable and consistent delivery We understand the importance of quality in our industry and take pride in providing our clients with the best possible service.

Infrastructure

Extrusion

We produce 55,000 kgs per day of Polypropylene tapes of various weights and strengths. Extrusion is a unique blend of raw materials that is extruded into tapes of different widths. This process allows for increased strength and durability in the tapes. They are then ready for weaving, providing a more consistent and seamless product

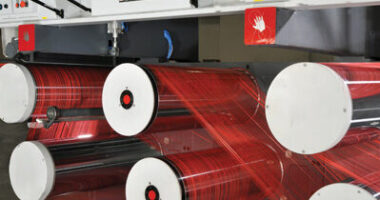

Lamination

We have a lamination plant which can produce from 1 meter to 4 meters and thickness based on customer. We laminate 90,000 meters per day.Lamination Polypropylene fabric is laminated with a semi-clear PP film that is bonded to the woven material to create a moisture barrier.

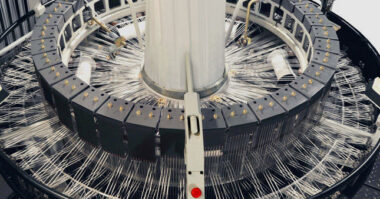

Circular Loom

We have circular looms from 6 shuttle to 10-shuttle looms where we can produce 50 cms – 240 cms tubular fabric. We produce 250,000 meters of fabrics per day. Weaving tape bobbins are a unique way to weave fabric and are ideal for a variety of applications. They are easy to use and create a clean, consistent weave.

Belt Cutting

The fabric in rolls is run through an automatic cutting machine and is cut to a specific size. This automatic process is adopted to get better accuracy in cut size. We have various types of fabric cutting like heat cutting, cold cutting, heat seal cutting, and ultrasonic cutting.

Printing

Our printing machines are powerful and efficient, ensuring accurate and high-quality printing. The body fabric panels are then fed into a printing machine to make a printing impression on the fabric. We have a flexo-graphic printing facility.

Liner Plants

FIBCs with liners increase the efficiency of bulk bags, they make filling and discharge easier, they help keep the shape of the bags intact, shield them from moisture and oxygen, and keep the product within safe and free from contamination.

Port Connectivity

Port Connectivity is a next-generation port technology that enables efficient and well-connected container ports. Port connectivity helps to connect to the world. Our factory is connected to major airports and seaports like Hazira port, Mundra port, and Nava Sheva port which help us to ship our goods across the countries. Our network provides customers with cost-effective manufacturing options and dependable International and domestic delivery. We are committed to offering our customers the best quality products at the most competitive prices. We are dedicated to providing the best quality products at the best competitive prices, and our team of experienced professionals is committed to providing you with the best possible service.